In our conversations with numerous clients, one of the most frustrating and infuriating issues they face during international procurement is receiving products in severely damaged shipping cartons, with some items even falling out of the torn boxes. To address this, we are committed to ensuring that our clients receive the correct quantity of products in perfect condition. This commitment has driven us to put in significant effort.

Choosing Sturdy Corrugated Shipping Boxes

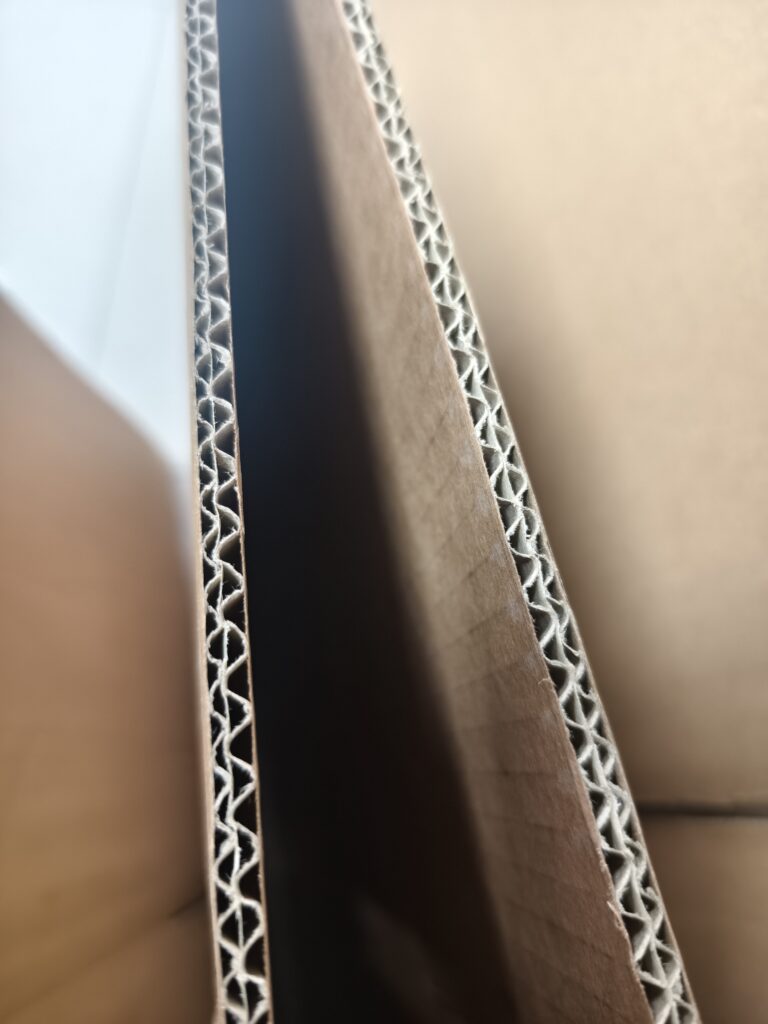

Our corrugated shipping boxes are made from reinforced corrugated material, featuring a triangular structure that provides mutual support, excellent mechanical strength, and flexibility. Even when subjected to external impacts and pressure, these boxes resist deformation and offer superior cushioning.

Moreover, our boxes are constructed with five layers of corrugated paper, ensuring both durability and the ability to bear substantial weight. Our boxes remain robust and durable even at around 22kg. However, when calculating packaging quantities and weights, we typically keep the total weight under 18kg.

Neat Product Arrangement Inside the Boxes

We prioritize neat product arrangement to maximize space efficiency, thereby reducing storage and shipping costs. Additionally, we maintain a 5mm gap between the products and the inner walls of the box. This prevents damage from excessive movement during transit due to large gaps, while also avoiding over-packing that could lead to product damage from compression.

Sturdy Exterior of the Boxes

As you can see, our boxes show no signs of bulging or deformation after being packed. The shipping images demonstrate that our boxes are both flexible and sturdy.

Given the relatively high additional costs and shipping fees associated with pallets, we flexibly determine whether to use palletized shipping for our products and cartons based on the order size. For smaller quantities, we do not opt for palletized packaging. However, when the quantity exceeds three pallets, we can arrange for the products and cartons to be palletized and shipped accordingly.

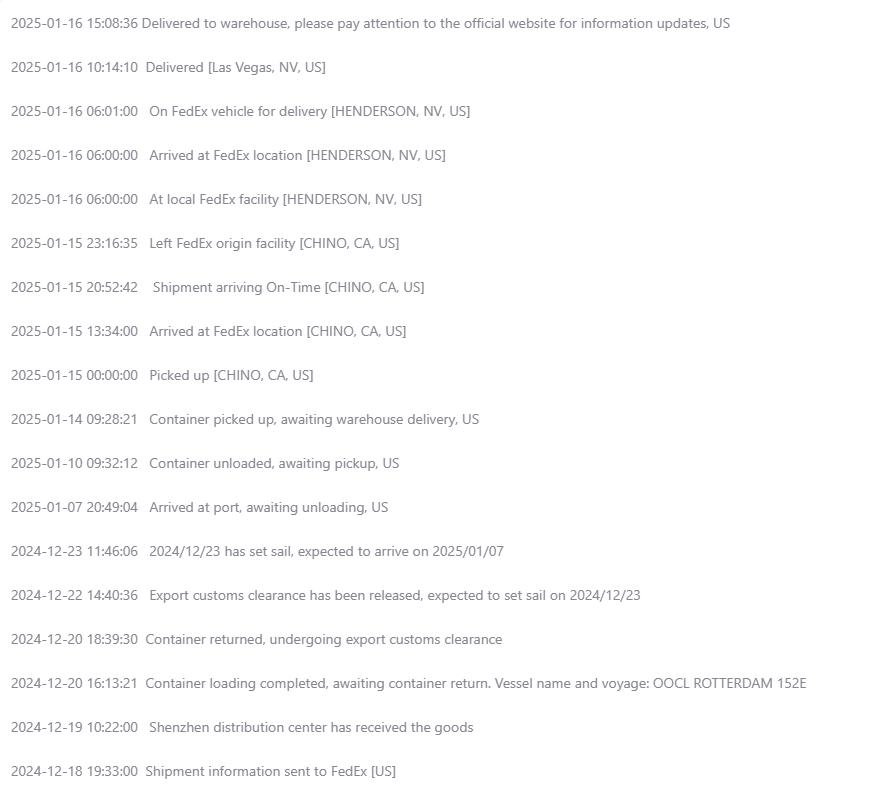

Boxes Remaining Intact After Multiple Transfers

Our shipping trajectory to U.S. clients shows that the boxes undergo numerous transfers: from our warehouse to the freight forwarder’s warehouse, into the shipping container, unloading at the destination country’s warehouse, pickup by the local courier, two additional courier transfers, and finally delivery. Each box undergoes at least eight transfers, a significant test of its durability.

However, our boxes withstand this test. Even after multiple transfers, clients receive their products with only minor creases or slight damage to the boxes, with no major deformations or significant damage.

Products in Perfect Condition Upon Unboxing

When clients open the boxes, the products inside are in perfect condition, flawless.

For every project and order, we customize the carton based on the products to ensure the most suitable packaging. We avoid any actions that could damage the boxes, such as cutting them during packing. We calculate the optimal packing method and always include an extra 1-3% of products to ensure that each order has whole numbers of carton, with each carton containing the same quantity of products.